(and how does this affect the nut factor?)

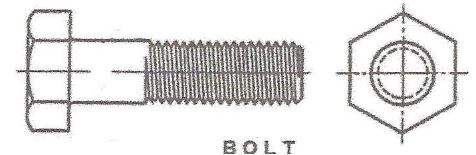

The terms “bolt“ and “capscrew” are commonly used interchangeably. But the variations between the two are fairly significant from a manufacturing perspective and assembly standpoints. What’s the difference? Why does it matter?

A bolt is designed for insertion through holes in assembled parts to mate with a nut and is intended to be tightened or released by turning that nut.

- A die seam across the bearing surface is permissible.

- The typical bolt is manufactured by the hot-forging process.

- Common fastener specifications, unless otherwise specified: ASTM A307-A, A354.

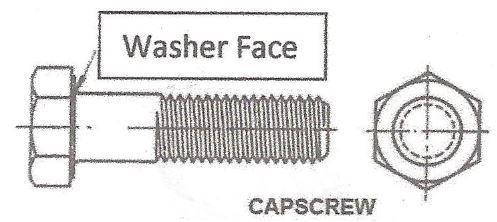

A capscrew is a fastener possessing capabilities which permit it to be inserted into holes in assembled parts, of mating with preformed internal threads and of being tightened or released by torquing its’ head.

- Flat washer facing under the head as described under ASME 18.2.1-1996.

- Usually manufactured by a cold-heading process or turned by CNC operation.

- Common fastener specifications are SAE J429 Grade 2, 5 and 8.

The primary difference: the washer face on the underside of the capscrew’s head.

This is important for two reasons:

- If a bolt is tightened by turning its’ head, the sharp corners of the hex head will dig into the joints’ bearing surface, using up part of the input energy to “machine” the mating face, instead of generating preload.

- Published K values are intended to be used when applying torque to a nut. These values will change in relation to fastener length and assembly running torque, if the torque is being read from the bolt head, instead of the nut. Preload will be reduced if mating parts have tight hole tolerances and are slightly mismatched, causing rubbing on the bolt shank.

A few other factors which will affect the preload attained:

- Number of times the bolt and nut have been re-used.

- Number, type and size of washers used in the joint.

- Whether the fastener is in the “dry” (as-received) condition or “lubricated” and which lubricant is used (light oil, anti-seize, grease and beeswax are common).