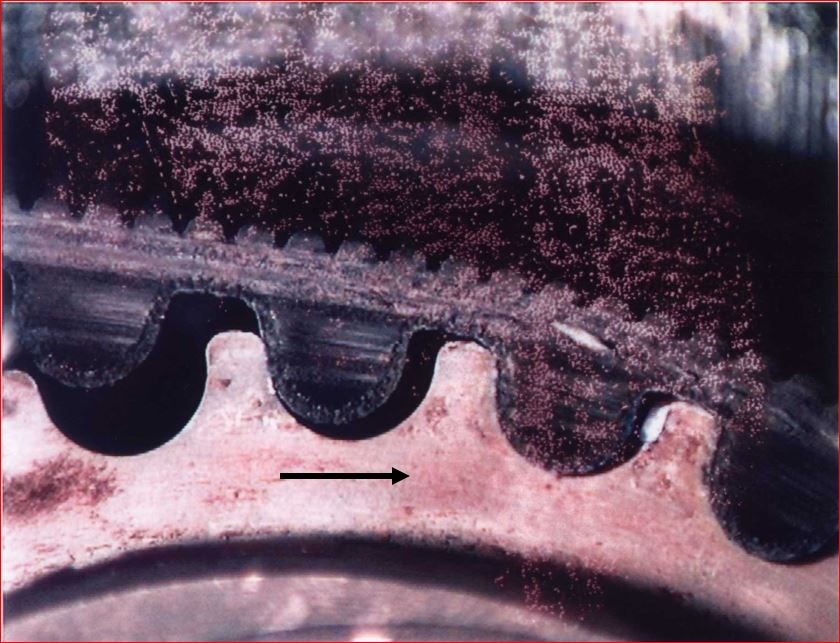

(Changing topics this time, the following is my response to an inquiry by a Harley rider as to expected belt drive system life on his H-D motorcycle.) Before answering your question, I need to mention that the condition of the 32-tooth transmission output sprocket controls belt life to a much greater degree than the 70-tooth rear sprocket. This is because the belt is wrapped around a much smaller pitch radius and has fewer teeth in engagement than the rear sprocket. The transmission sprocket teeth will therefore wear at a faster rate than the rear sprocket for any given mileage traveled. As the teeth of the front sprocket wear, due to the action of grit, sand or debris, the rounded tip profile flattens off on the top and also on the face or upper flank of each tooth. Over time, this begins to create a “corner” which digs away at the base of the belt teeth on the driven side. Cracks will develop and a tooth will eventually be torn from the belt, rendering it useless. Also keep in mind that the action of the belt teeth entering the transmission sprocket teeth is one of heavy, sliding pressure between the flanks of both teeth and major deflection of the belt teeth. The rear sprocket is cast from aluminum with the teeth receiving hard-chrome plating to protect them from abrasive wear. This sprocket is susceptible to damage from stones or other small, hard objects which are thrown up into the belt/rear sprocket interface on the lower span, causing chips in the chrome plating. (See the attached photo of a belt under hard acceleration)

There are at least two answers to your question, both dependent upon the environment in which you ride your vehicle. If the majority of your riding is done on paved roads with little or no grit or sand involved, I would expect your drive system to go in excess of 100,000 miles without problems. We have many examples of riders who have gone this far and have changed the belt and sprockets when the primary was off, “just to be safe”. I recommend this approach. The second possibility is that you ride on mostly unpaved or gravel roads, in which case, your belt may only go 40,000 to 60,000 miles depending on how quickly your transmission sprocket wears. A third possibility is that your belt/rear sprocket interface ingests a stone. If it is a soft stone, it will be crushed into powder and may or may not cause a chip in the chrome plating. If it is a very hard stone, it will be driven through the belt, severing one or more tensile cords, depending upon the size of the stone. It may also chip the sprocket. This occurrence is quite noticeable to the rider, resulting in a loud “bang” and a significant “jerk” in the bike’s forward motion as the drive tries to “eat” the stone. If the puncture occurs near the edge of the belt, it will fail almost immediately. If it is fairly well centered in the belt, it can be driven home (carefully), but will fail in the near future, due to increased unit loading of the remaining, undamaged belt cross-section. Another cause of the loud bang and jerk is if the belt was running very loose and tried to throw a loop of excess belt slack over the transmission sprocket during either a hard downshift or a hard bump which compressed the rear suspension. This creates the phenomenon referred to as “ratcheting”. A belt failure due to ratcheting is characterized by 1/4” – 3/8” long “fingers” of tensile cords protruding from both ends of the break.

I recommend that you jack the rear wheel of your vehicle off the ground, remove the debris deflector and belt guard and inspect the drive system as follows:

Transmission sprocket – Look for heavy pitting, which indicates a high degree of abrasive wear. Look for “sharp” corners at the top of the tooth, where the face or flank of the tooth joins the top or tip radii. This should feel like a smooth transition rather than give the impression of an edge across the face width of the tooth. Heavily-worn teeth will typically have a flat-appearing area across the top of the tooth. If this flat is 1/8″ wide or more, I would recommend replacing the transmission sprocket along with the belt. (See attached sketch for clarification)

Belt– Inspect the edges of the belt for cuts or unusual wear patterns. Some beveling of the outside edge is common and by itself is not usually harmful, but it is an indicator of misalignment of the sprockets. Look at the outside, ribbed surface for signs of obvious stone puncture. You can’t always see this damage easily from the outside of the belt, so look closely. On the inside or toothed portion of the belt, look for signs of the tensile cords showing through in the root of the belt groove. They should be covered by one layer of nylon facing and one layer of polyethylene. If these layers are worn through, the tensile cords are exposed and visible. This is an indication of the transmission sprocket tooth tip diameter being severely worn. In this event, belt failure is impending, as the sprocket tooth tips will continue to scratch away at the tensile cords until they wear through. Also look for signs of cracking at the base of the belt teeth where the “corner” of worn transmission sprocket teeth would contact them. Any signs of puncture or cracking would dictate replacement of the belt. A rule of thumb H-D test facilities use is that if the belt is replaced for reasons other than stone damage, the transmission and rear sprockets are generally replaced also. A worn front sprocket tooth profile will drastically reduce the life of a new belt if it is not changed out at the same time.

Rear Sprocket – The rear sprocket replacement can be a judgement call, based on general appearance. The chrome plating is lightest in the bottom or root of the groove. If in doubt whether the plating has been worn off, drag a scribe or the sharp point of a knife blade across the root with medium pressure. If it slides across without digging in, the chrome is still good. If you can feel it digging in and it leaves a visible mark, you are cutting into the bare aluminum. A knife point will not penetrate the chrome plating. Inspect each tooth for major chrome chips with sharp edges or for gouges caused by a hard object. If large enough to be harmful, both of these will leave a corresponding pattern in the belt face. Loss of chrome or major tooth damage should be cause for replacement of the rear sprocket.

I hope the above information is adequate to help you in your decision whether to replace your belt or not. I’ve attached a visual on belt handling precautions and the effect of low belt tension to help you get the highest mileage from your belt drive.