Typically, with a nut and bolt you rely on approximately 15% metal-to-metal contact in the threads. Therefore, 85% of the inter-thread space is open and can be filled and bonded by anaerobic thread locking materials. They also provide excellent sealing against most liquids. Thread lockers can also prevent or reduce galvanic corrosion between dissimilar metals, such as a magnesium casting and a steel cap screw. Chemical thread lockers come in both dry, pre-applied coatings suitable for high-volume assembly and liquids, which are manually applied to individual bolts immediately prior to installation. The pre-applied coatings are supplied by the fastener supplier according to IFI 125 and IFI 525. Examples of dry coatings are Dri-Loc or ScotchGrip.

The left screw was from production stock. The right screw was a four year old screw from the PPAP approval sample. The production screw threads were over-filled and caused severe drag against the installation torque tool. As a result, the desired preload was not achieved and fatigue failures of the fasteners soon resulted.

NOTE – Some chemical thread locking compounds are incompatible with ABS plastic and were identified as the cause of failure in an automotive application. The Loctite Design Guide for Bonding Plastics (Vol. 2, 2000) specifically warns that their anaerobic adhesives are “incompatible” with ABS plastic. This is likely true for other brands as well.

There are no problems associated with measuring the dynamic installation torque when using threadlocking adhesives in a joint. Problems do arise when the assembly torque must be checked sometime after assembly. If the cured bond is broken to check the torque, the vibration resistance of the assembly will be impaired. Also, the hardened adhesive in the threads increases friction characteristics so that less torque goes into achieving the desired preload during re-tightening. For these reasons, any of the usual methods for post-assembly torque auditing are unsuitable for threads which have been bonded by adhesives or liquid threadlockers. The one exception is when torques are verified within a short time period after initial assembly. Consult the manufacturer’s instructions regarding cure times for guidance on this procedure.

To check the torque on a fastener that has a lock patch or liquid thread locker which has bonded:

- Set the torque wrench for the lowest setting in the specified torque range

- Attempt to tighten the fastener to the set torque. If the fastener does not move and the lowest setting is satisfied (torque wrench clicks), then the proper torque has been achieved.

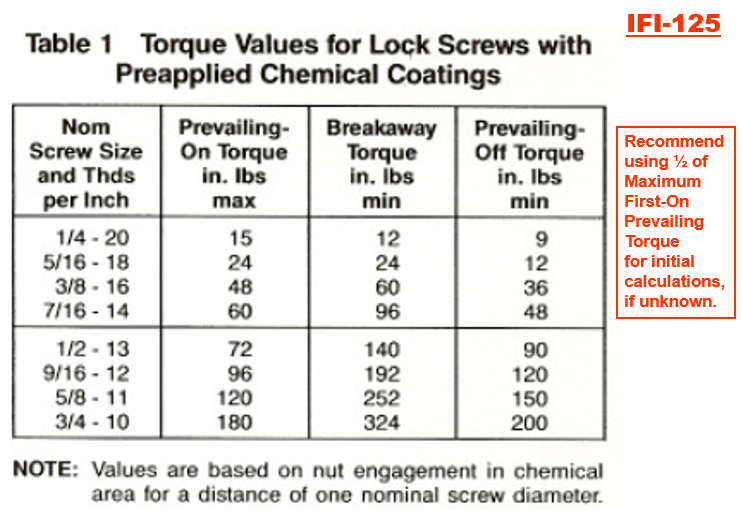

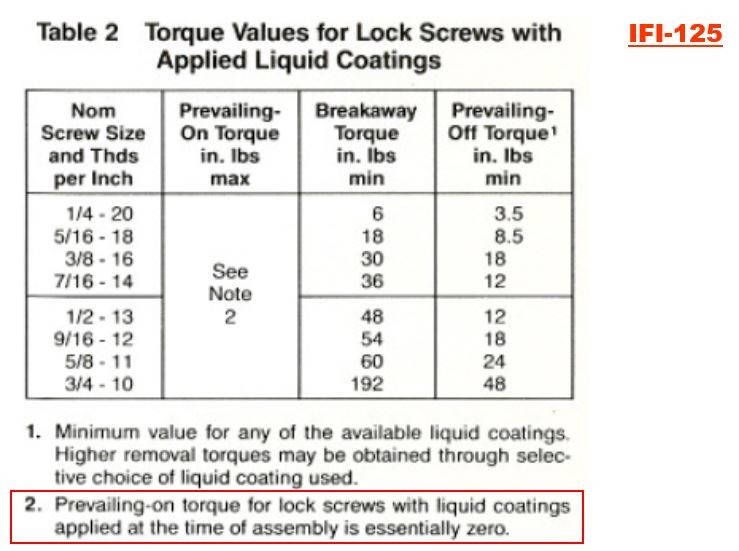

Your calculations should include the effects of the prevailing torque, or drag, as follows:

Installation torque, T in-lbs = (k * Fi * d) – (prevailing torque, in-lbs)

When a bolted joint assembled with anaerobic thread locker is disassembled for service, additional operations are required before re-assembly. The cured thread locking compound remaining in and on the joint’s threads must be removed. Failure to do so will cause a high drag on the threads during re-assembly. As a result, insufficient clamp load will be attained by tightening the fastener to the manufacturer’s specified torque.

External threads may be wire brushed or cleaned by running a die over them. Internal threads can be cleaned by running a tap in and out with no oil involved, as this will only prevent adhesion of the new threadlocking compound.

Re-assembly may then be done using liquid anaerobic thread lockers, which serve as somewhat of a lubricant for installation. A word of caution on the selection of liquid thread lockers: Some of the high-strength liquids, such as Loctite 271, may require the application of heat to the bolt head to loosen the joint sufficiently for disassembly. There are various strengths to choose from, so use only as much locking capability as needed for the application.

NOTE: Do not specify wet or dry anaerobic thread lockers by color alone, as the colors vary between manufacturers. State the manufacturer’s name, product name and numerical identification to be certain you get the actual product you need.